Energy-Saving, Light-Reflecting Polished Concrete Floors

Light Reflectivity Energy Savings

As energy conservation and green building solutions have grown in popularity, common lighting systems have significantly improved. More industrial, commercial and retail spaces are incorporating these advanced, energy-efficient means of lighting into their operating expense. However, there is one thing that the lighting engineers cannot control; REFLECTION.

Installing light-colored polished concrete floors can help save energy and reduce lighting bills by amplifying the amount of natural light entering a building during the day and reducing the need for artificial light at night. For some projects, high reflectant concrete floors achieve LEED certification and slash energy consumption.

Light reflecting polished concrete floors combines the durability, low maintenance and green properties of concrete with the property of retroreflection. Retroreflective surfaces precisely reflect incident light (sunlight or artificial light) back towards the light source. The concrete surface is activated by light from both the light source and the recipient. At any given moment the reflection effect can become perceptible, and the concrete switches from a passive to an active state.

Highly reflective surfaces are generally mirrored so that light “bounces off” at a supplementary angle. The black arrows represent incoming light, while the colored arrows represent reflected, or refracted light.

Polishing Technique Affects the Outcome

Grinding techniques, diamond selection and equipment will affect the final polish and light reflectivity. Improper grinding may leave scratches in the finished surface which will disrupt/deflect the light reflectivity. Every pass of each diamond disk will impart a “scratch pattern” to the concrete surface. It’s important to take the proper amount of time for each pass so that the diamonds grind and polish every square inch consistently. Analysis of the original flooring tells our production teams what products and techniques are required to ensure a glossy finis

Different Levels of Reflective Polished Concrete

High Gloss Finish

A decorative, high gloss finish is an ideal application for showrooms, high-end real estate and areas where aesthetic properties like high shine and sharp reflection are top priority. The result is a surface that stands out and offers exceptional durability.

- Reflective and decorative finish

- Extremely high quality and durability

- Hygienic and easy to clean

- Exceptionally resistant to abrasion

Medium Gloss Industrial Finish

A medium gloss finish is often considered an industrial finish. This application is ideal for retail areas, shop fronts and indoor public spaces. The result is a floor that offers functionality and low maintenance but is still aesthetically pleasing.

- Easy to clean and maintain

- Resistant to wear and spills

- Abrasion-resistant

- Slip-resistant

- Minimal lifetime cost

Matte Finish

A low gloss finish is ideal for commercial floors. This application targets large areas such as warehouses and department stores where flooring functionality is a higher priority than decorative appeal. The result is a hardwearing floor that offers a safer and cleaner environment.

- Minimal lifetime cost

- Withstands the toughest use

- Slip-resistant

- Resistant to spills, abrasion, oils and dusting

- Easy to clean

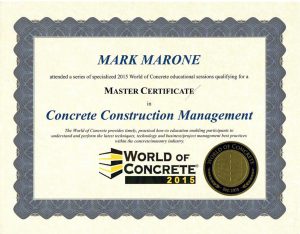

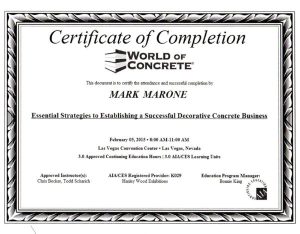

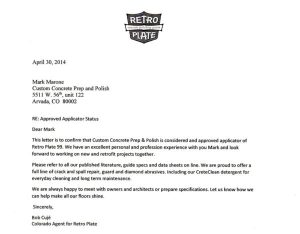

Masters of our craft