Services

Quick Links

Polished Concrete

Polished concrete floors have become very popular in retail, office and industrial applications. It is very durable, easy to clean and requires very little maintenance. A polished concrete floor has a glossy, mirror-like finish. The design options for polished concrete are vast. You can choose nearly any color, create patterns with saw cuts, or embed aggregates or interesting objects into the concrete prior to polishing.

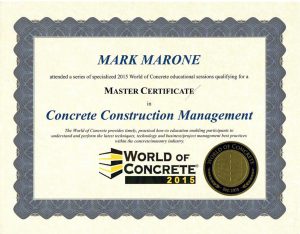

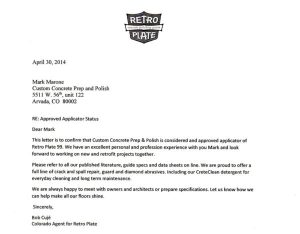

Advanced Floor Products is the first in the concrete polishing industry to combine the effects of diamond grinding and polishing with a one-application densifying sealer. The RetroPlate Concrete Polishing System® is the innovative combination of diamond grinding, polishing, and the RetroPlate® densifier.

Stained Concrete

Staining interior concrete floors has become a popular alternative to carpet or hardwood floors. There are three ways to color concrete flooring: water-based stains, solvent-based dyes, and acid-based stains.

Water-based stains can achieve nearly any color. Unlike acid-based stains, they don’t interact with the concrete that you’re staining, so the color will stay consistent. Water-based stains are generally easier to apply, and cleanup is minimal. They’re also low VOC. There are environmentally friendly products that are safer to work with than an acid-based stain.

Solvent-based dyes come in a variety of colors that can be customized by diluting the product. Solvent-based dyes do not penetrate deeply into concrete, so they enhance rather than hide concrete’s natural variations. Since the chemicals in dyes do not break down any of the ingredients in concrete, you can apply dyes without worrying about causing any damage.

Acid-based stains typically come in earth tones and are translucent, so it will pick up the variations in the concrete. This process will often take on a more natural look that mimics wood or stone. The color palette is more limited, but the stain typically lasts longer than water-based.

AmeriPolish Classic dyes penetrate into the surface of the concrete slab for extremely long lasting color that will not wear from daily usage. Classic dyes can be used as a base color or touch up for concrete that has received integral color, dry shake hardeners, acid stains, or even layered to create a truly unique, mottled effect.

Sealed Concrete

Concrete sealers are applied to concrete to protect it from surface damage, corrosion, and staining. They either block the pores in the concrete to reduce the absorption of water and salts or form an impermeable layer that prevents such materials from passing.

Research from major concrete authorities, including the American Concrete Institute, the Portland Cement Association, and the National Ready Mix Concrete Association, confirm that most concrete damage is attributable to surface moisture intrusion. The most pervasive form of concrete damage is surface scaling from freeze/thaw. Other forms of damage include alkali-silica reaction (ASR), chemical intrusion, and corrosion of steel reinforcements.

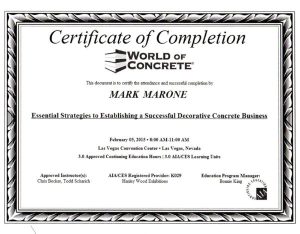

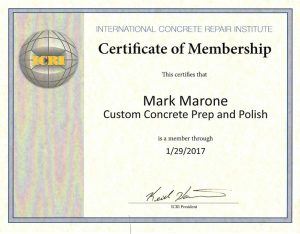

Masters of our craft

Epoxy Coatings

A popular application for garages, workrooms, machine shops or clean rooms is an epoxy coating. These coatings can be applied using many different kinds of chips or quartz in a multitude of colors. They can also be applied without chips or quartz and also come in many stand-alone colors. Epoxy coatings are extremely durable and are great for garages, airplane hangars, warehouses, restaurant kitchens and many other areas.

Arizona Polymer Flooring Epoxy 100 is used as a general purpose coating for concrete floors and as a primer under epoxy, polyurethane and acrylic materials. Epoxy 100 is a two component water-based epoxy system that features ease of application, very low odor and excellent overall coating performance. This material cures blush free over a wide range of temperatures and adheres tenaciously to a variety of substrates including damp or wet concrete. Because of its affinity for moisture and inherent alkalinity resistance, Epoxy 100 may be used over green concrete with proper surface preparation.

Cementitious Urethane

CastorCrete® is Urethane Modified Concrete designed for use in the most demanding food and beverage processing areas where high resistance to impact, abrasion and chemical resistance to organic food acids is required. CastorCrete® is formulated with renewable raw materials and contains no VOCs, making it a viable option for environmentally friendly projects. It offers exceptional thermal shock resistance and is available with an anti-microbial additive to inhibit the growth of bacteria and microorganisms

Polyaspartic Floor Coating

Polyaspartic Floor Coatings can be applied to nearly any concrete surface at nearly any temperature. It bonds easily, cures to full strength within half an hour, is flexible enough to bridge small cracks, can withstand high temperatures when cured, and has superior stain and UV resistance.

Coatings can be applied in stand-alone colors or with a color chip, quartz, or mica broadcast. Choose your combination for a one-of-a-kind custom floor.

HP Spartacote Sparta-Flex® is a fast-curing two-part polyaspartic aliphatic polyurea sealer/finish coating for both decorative and protective applications. As an industrial maintenance coating, this material is self-priming and may be applied in single or multiple coats by brush, roller, broom, squeegee or sprayer of varying thicknesses to a variety of substrates including concrete and metal. It can be applied over decorative concrete surfaces such as acid, color-or dye-stained concrete, as a pigmented high performance coating, or employed within seamless multi-build chip/quartz flooring systems. Important characteristics of Sparta-Flex® are its excellent penetration and bond strength, UV resistance and superior color/gloss retention.

Moisture Mitigation

Concrete floor slabs contain excess moisture that can damage many types of floor finishes. Moisture comes from two principal sources; free water from the concrete mix and from the earth beneath the slab. Moisture mitigation requires low-viscosity high-density resins that penetrate deep into the substrate to effectively reduce moisture vapor emission rates.

Arizona Polymer VaporSolve 100 LP is a specially formulated 100% solids epoxy coating designed to comply with ASTM F-3010 and is for use over concrete with high moisture levels for the purpose of isolating the concrete from moisture sensitive flooring.

Surface Prep

An essential part of getting the floor of your dreams is making sure the surface is prepped correctly before your application of choice is applied. At Custom Concrete Prep and Polish, we have our own state-of-the-art grinding and shot blasting equipment. The grinders are used to remove any existing material and open up the concrete surface to accept color and sealers. The shot blaster gives the floor a nice, rough profile that assures product adhesion when applying coatings, self-leveling underlayments or cementitious overlayments. Whether you need a coating or leveling a floor to apply wood flooring, tiling, or VCT – a floor is only as good as what’s underneath it.

Floor preparation is a special point of emphasis for us at Custom Concrete Prep and Polish. We pride ourselves on laying a good foundation so that your flooring will last for a long time. We would be happy to provide our grinding and shot blasting services as stand-alone jobs if needed.

Floor Leveling

Many of our customers need their floor leveled so their choice of new flooring can be installed correctly. In these instances, we can grind or scarify the high areas and/or fill in the low areas until the specifications of the new flooring can be met. A common floor leveling technique is the use of underlayments. The primary purpose of underlayments is as a thin topping to level, smooth, or fix imperfections in concrete substrates prior to the application of concrete coatings. Underlayments require care in installation. Inadequate concrete surface preparation and priming might lead to severe pinholing or bubbling. Most self-levelers are typically applied at thicknesses of 1/4 inch or greater, allowing them to effectively cover minor flaws and compensate for height variances.

Cement-based micro toppings provide a clean canvas for decorative treatments, such as stains, dyes and stenciled patterns. Some systems come pre-tinted in a wide range of colors, while others can be custom-tinted by mixing in the desired amount of liquid coloring agent. Interesting color variations can be achieved by applying layers of different hues.