More restrictive regulations are requiring low volatile organic compounds (VOC) in construction materials such as paint and coatings applications. Solvents typically are the prime components responsible for VOCs, which builders are avoiding as they move toward more sustainable building practices. It is important to know the characteristics of concrete flooring sealers, which can vary from very high VOC (more than 400 grams per liter) to very low VOC (less than 100 grams per liter).

Concrete sealers come in both water-based varieties (typically lower VOC) and solvent-based types (normally high VOC). Both water- and solvent-based sealers act as decorative and protective topcoats for concrete. They are designed to protect the concrete from wear and tear and are the primary means of providing chemical and stain resistance for concrete. These sealers add to aesthetics, including gloss and long-term color enhancement. For both water- and solvent-based sealers, the polymer remains on the concrete surface. This is why a sealed concrete surface often appears glossy.

Water-Based Sealers are Low VOC

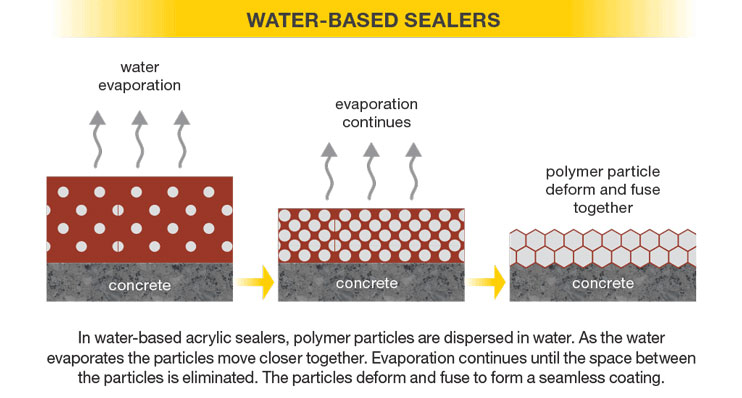

In the case of a water-based sealer, the polymer particles are dispersed in water. When the sealer is applied to concrete, the water evaporates and the polymer particles move closer together. As the evaporation of water continues, the polymer particles begin to deform and fuse together, eventually forming a continuous clear coating.

With a solvent-based sealer, polymers are not present as separate particles. Instead, the polymer and solvent form a continuous, clear polymer solution. When the solvent evaporates from a solvent-based sealer, the polymer chains are drawn closer together and eventually entangle.

The Differences Between Water-Based Sealers and Solvent-Based Sealers

- Appearance: Solvent-based sealers have a tendency to darken a surface. Because of this, it can be hard to predict exactly what the finished color will be. Water-based acrylic sealers are available in gloss or matte finishes. Finishing problems such as bubbles or streaks are less likely with water-based acrylic sealers.

- Low VOC: Water-based acrylic sealers don’t off-gas VOCs into the atmosphere. This is healthier for the installers and those who work in the building after the floor is installed.

- Tough and durable. The most important similarity between the two types of sealers is they both work to protect the concrete. This can last for two to three years with the best performing acrylic sealers exposed outdoors. Both types also will provide stain protection, so various spilled food, chemicals, and automotive stains typically can be removed before permanent staining occurs.

- Easy to apply. Both water- and solvent-based sealers typically are available in fully formulated, ready-to-apply variations. They can be either sprayed or rolled on, depending on the project.

- UV resistance. Because 100% acrylic sealers are fully transparent to UV light, they will not undergo the photochemical breakdown experienced by more UV-absorbent polymers, such as styrene-acrylics, nonaliphatic polyurethanes, and most epoxies. The UV resistance provided by 100% acrylic-based concrete sealers can lead to extended service and protection.

L&M™ LUMISEAL FX™ is a Preferred Low-VOC Coating Formula

L&M™ LUMISEAL FX™ is a water-based, non-yellowing, blush resistant curing and sealing compound designed to provide attractive, high gloss sealing qualities. L&M LUMISEAL FX is formulated with advanced low-VOC, self-crosslinking emulsion chemistry, providing a very durable film and excellent early water-resistance to whitening or blistering. L&M LUMISEAL FX is suitable for use on interior and exterior, horizontal and vertical surfaces.

Benefits include:

- Non-blushing formula, resists whitening.

- Non-yellowing, pure acrylic formulation.

- Low VOC, Low Odor

- Recommended for interior and exterior use.

- Compatible with previously sealed concrete with minimal preparation.

- Provides additional stain protection to polished concrete.

- Resists black tire marks.